Entwicklung technisch-wissenschaftlicher Software

Wir entwickeln für Sie technisch wissenschaftliche Software unter Windows NT / 2000 / XP / Vista / 7 / 8 sowie unter Windows CE.

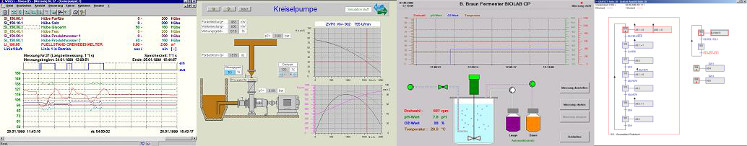

Die Software für das Automatisierungssystem ![]() wurde und wird weiterhin vollständig in unserem Hause entwickelt. Neben der Programmierung der Oberflächen gehören dazu ebenso die Programmierung der Steuerungs- und Regelungsfunktionen und der Prozessschnittstellen, wie OPC, TCP/IP Modbus, Ethercat, Fernwirkprotokoll, und weitere.

wurde und wird weiterhin vollständig in unserem Hause entwickelt. Neben der Programmierung der Oberflächen gehören dazu ebenso die Programmierung der Steuerungs- und Regelungsfunktionen und der Prozessschnittstellen, wie OPC, TCP/IP Modbus, Ethercat, Fernwirkprotokoll, und weitere.

Auch erstellen wir Software, die speziell auf Ihre Bedürfnisse zugeschnitten ist, dazu zählen:

- spezielle OPC-Server, die Sie mit Ihren Produkten verkaufen können

- Datenbanken,

- Prozessschnittstellen,

- Microsoft Office Plugins.

Mehr Informationen finden Sie hier:

Regleroptimierung

Sind Sie mit Ihrem Regelkreisverhalten nicht zufrieden, optimieren wir Ihre Regelung. Das Optimieren von Regelungen umfasst Aufgaben vom einfachen Verbessern eingestellter Reglerparameter bis zu umfangreichen Untersuchungen des Systemverhaltens Ihrer Anlage. Hierbei kann es sinnvoll sein, Ihren Prozess mathematisch zu beschreiben und zu simulieren, um an der Prozesssimulation Reglerstrukturen zu erarbeiten und zu testen, bevor diese an der realen Anlage in Betrieb genommen werden.

Process simulation

We build up dynamic process simulations, e.g. mixing container reactors, distillation plants, bioreactors and other processes from the field of process engineering.

Likewise for the optimisation of control systems we simulate sub-processes of thermical and mechanical systems to analyse the behaviour and to generate optimal control systems.

When testing a newly programmed control for a PLC is can be useful to first try the control system in a simulation.

The various and simple options of WinErs as a simulation system support simulation projects. All SCHOOP-didactic products (Practical Training on Control Engineering I, LC2030 Training, BioProcessTrainer) are dynamic simulations built up with WinErs.

Examples:

Videos:

Stirred Tank Reactor-Animation

Further examples may be found in WinErs Demo Version. (download is possible after registration)

More Information:

Please contact us for further information [contact]

Control engineering

{gallery }steuern_regeln{/gallery}

We built up open and closed-loop control systems with our SCADA-system WinErs.

The complete automation runs on a PC, hence no additional PLC is necessary and you may easily monitor the automation. The usual process interface is is a field bus system with ethernet connection over TCP/IP Modbus or EtherCat.

- We optimise closed-loop control systems. The Optimisation of control systems includes tasks from simply optimising control parameters to extensivly analysing the behaviour of your plant. In some cases it is useful to describe the system mathematically and try the control system in a simulation, before commissioning it on th real plant.

- Due to the close connection between control engineering and simulation engineering we develop process simulations, with wich you may test your control system before commisioning the plant.

References

All reference projectsApplication Examples:

Examples for visualisation, controlling and pross data archiving may be found in WinErs Demo Version. (download is possible after registration)

More Information:

Please contact us for further information [contact]

Our industrial services include automation tasks from project planning over control set up and configuration to commissioning. We respond to customer needs and generate optimal solutions.

Our main tasks include the development and realisation of control systems, the visualisation of processes, set up of alarms and reports and the design of data archives. We realise these tasks with our SCADA-system WinErs, which is completely developed and maintained inhouse.

We develop cost-effective automations of plants with up to thousands of signals or we extend your existing plants by setting up better control systems, operation and view units, alarming and archiving systems, aswell as telecontrol systems.

We optimise closed-loop control systems. The Optimisation of control systems includes tasks from simply optimising control parameters to extensivly analysing the behaviour of your plant. In some cases it is useful to describe the system mathematically and try the control system in a simulation, before commissioning it on th real plant.

In industrial tasks it is often necessary to use redundant systems. We built up and commission systems in this sensible area:

- Redundant closed and open-loop control systems

- Redundant protocolling in power plants

- Redundant process control systems

- Redundant transmission systems for telecontrol protocols

- Redundant process data archiving and storing systems

References:

All Reference ProjectsApplication example:

Examples for visualisation, controlling and pross data archiving may be found in WinErs Demo Version. (download is possible after registration)

More Information:

Please contact us for further information [contact]