Boards

Unsere Boards dienen als kostengünstige Anwendung für die Schulung von Regelungs- und Steuerungstechnik.

Lernsysteme

Crossroads-Board bietet mit 30 Leuchtdioden und 14 Sensoren bietet das Modell vielfältige Aufgabenstellungen.

Mit der Bio-Refit Box einfach vorhandene Anlagen und Bioreaktoren neu zu automatisieren und sie über den PC zu bedienen.

Zur Ergänzung unser Software haben wir auf Kundenwunsch Ausbildungsanlagen entwickelt, mit denen an realen Prozessen steuerungs- und regelungstechnische Aufgabenstellungen bearbeitet werden können.

Die Anlage LC2030 gibt es natürlich auch als reine Simulationen, so dass die Möglichkeit besteht, mit Gruppen von Auszubildenden an der Simulation zu arbeiten, während eine Gruppe sich mit der realen Anlage beschäftigt.

Ausbildungsbioreaktor BC1010

| Reaktoreinheit |

|---|

| Reaktorgefäß mit Edelstahldeckel |

| Drei Korrekturmittel-Flaschen (Säure, Lauge, Antischaum) |

| 1 Rührer und 3 Pumpen |

| Tischgestell mit Edelstahl-Auffangwanne |

| Beheizung mit Heizstab oder als als Doppelmantelreaktor |

| Messgrößen | |

|---|---|

| pH-Wert | Redoxpotential |

| Leitfähigkeit | Sauerstoff |

| Temperatur | |

| Prozessleitsystem |

|---|

| Darstellung der Messdaten numerisch oder grafisch in intuitiven Prozessbildern |

| Alle Messdaten werden archiviert und können ausgewertet, sowie exportiert werden |

| Steuerungen und Regelungen werden über eine Soft-SPS ausgeführt |

| Elektronikbox |

|---|

| Dient als Schaltschrank mit: |

| Messverstärker für die verwendeten Sonden |

| Weitere analoge und binäre Ein- und Ausgänge |

| Wahlweise als Schaltschrank oder im Tischgehäuse |

Verwandte Produkte:

BioProcessTrainer: Experimente mit S.cerevisiae in einem simulierten Bioreaktor [mehr].

WinErs Laborversion: Erstellen Sie eine individuelle Steuerung, Regelung und Prozessvisualisierung [mehr].

Mehr Information:

Preis auf Anfrage

Rufen Sie uns gerne an, wenn Sie weitere Fragen haben. [Kontakt]

Laborkläranlage für die Wasseranalyse

There are no images in the gallery.

Verwandte Produkte:

WinErs Laborversion: Erstellen Sie eine individuelle Steuerung, Regelung und Prozessvisualisierung [mehr].

Rührkesselreaktor Praktikum: Über zwei Vorratsbehälter wird ein Reaktorbehälter befüllt. Es findet eine exotherme chemische Reaktion statt. Die Anlage kann vollständig per Hand gefahren werden [mehr].

Mehr Information:

Rufen Sie uns gerne an, wenn Sie weitere Fragen haben. [Kontakt]

LC2030 Workstation

Description

The LC2030 workstation was designed for training in control engineering. It offers a wide range of training options, from simple control tasks to different closed loop control systems

Three float switches and a pressure sensor detect the level. The level can be changed using three pumps. Switches and buttons on the control panel enable extended operation. Signal LEDs enable the display of errors and process statuses.

All analog signals with 2..10V and all binary signals with 24V are available on the control panel of the system via 4 mm safety laboratory sockets. The system can be connected to the PC via I/O boards. The optional LC2030 Training serves as a complete process control system for the system with visualization. The training system can also be operated with all standard control and regulation units (PLC, industrial controller, etc.).

Details and Options

The training system in this configuration allows various control engineering experiments to be carried out and consists of the following components:

- Adjustable pump for level control and/or flow control

The adjustable pump is located in the tank drain and is coupled with a level sensor. This enables level control and flow control. In conjunction with the controllable valve, flow control and level control can be coupled together. The pump is controlled via a frequency converter, which is supplied with 0 - 10 V via safety laboratory sockets. - Pressure transmitter for level measurement/control

The pressure transducer supplies a 2 -10V signal to the laboratory sockets. In combination with the controllable pump or the controllable valve, the level can be continuously controlled. - Flow sensor for controllable valve (optional)

The 0 - 10V of the flow sensor are routed to safety laboratory sockets. The flow sensor measures the inflow downstream of the controllable valve. The adjustable valve can be used to implement flow control. This flow control in the inflow and a level control via the controllable pump in the outflow can be coupled together. The flow control then acts as a disturbance variable on the level control. - Adjustable control valve for level/flow control (optional)

The control valve controls the inflow of the tank and can be used to implement level control and flow control. Flow control and level control can be coupled with each other via a controllable valve and controllable pump. It is controlled with 0 - 10 V via safety laboratory sockets. - Flow sensor for adjustable pump (optional)

This flow sensor measures the outflow via the controllable pump. The flow control in the outflow and the level control via the inflow can be coupled together. The flow control then acts as a disturbance variable on the level control.

The analog output signal of the sensor (0 - 10 V) is routed to safety laboratory sockets. - Pressure sensor for controllable pump in the drain pipe (optional)

The pressure control consists of a sensor, a manual valve and a pressure gauge for reading the pressure. The 2 - 10V of the sensor can be tapped on the laboratory sockets.

The pressure (max. 0.4 bar) is generated via the adjustable pump. - Heating element, Pt100 temperature sensor and additional circulation pump for temperature control (optional)

The heating rod enables the water to be heated. The heating rod is switched on/off via a 24V DC signal. The temperature sensor supplies the temperature as 0 - 10V to the laboratory sockets. A circulation pump ensures that the water is mixed more evenly. The circulation pump is permanently installed in the training system, while the heating rod and temperature sensor are attached to the top of the tank and can be removed if necessary. - Cooler with 2 fans to speed up the cooling process (optional)

The cooling system consists of a water/air cooler and two fans and enables the cooling process of the water to be accelerated using temperature control. The fans are controlled via a 24 V DC signal.

The cooling system is placed separately next to the training system and connected via the hoses supplied. - Measuring cable set (optional)

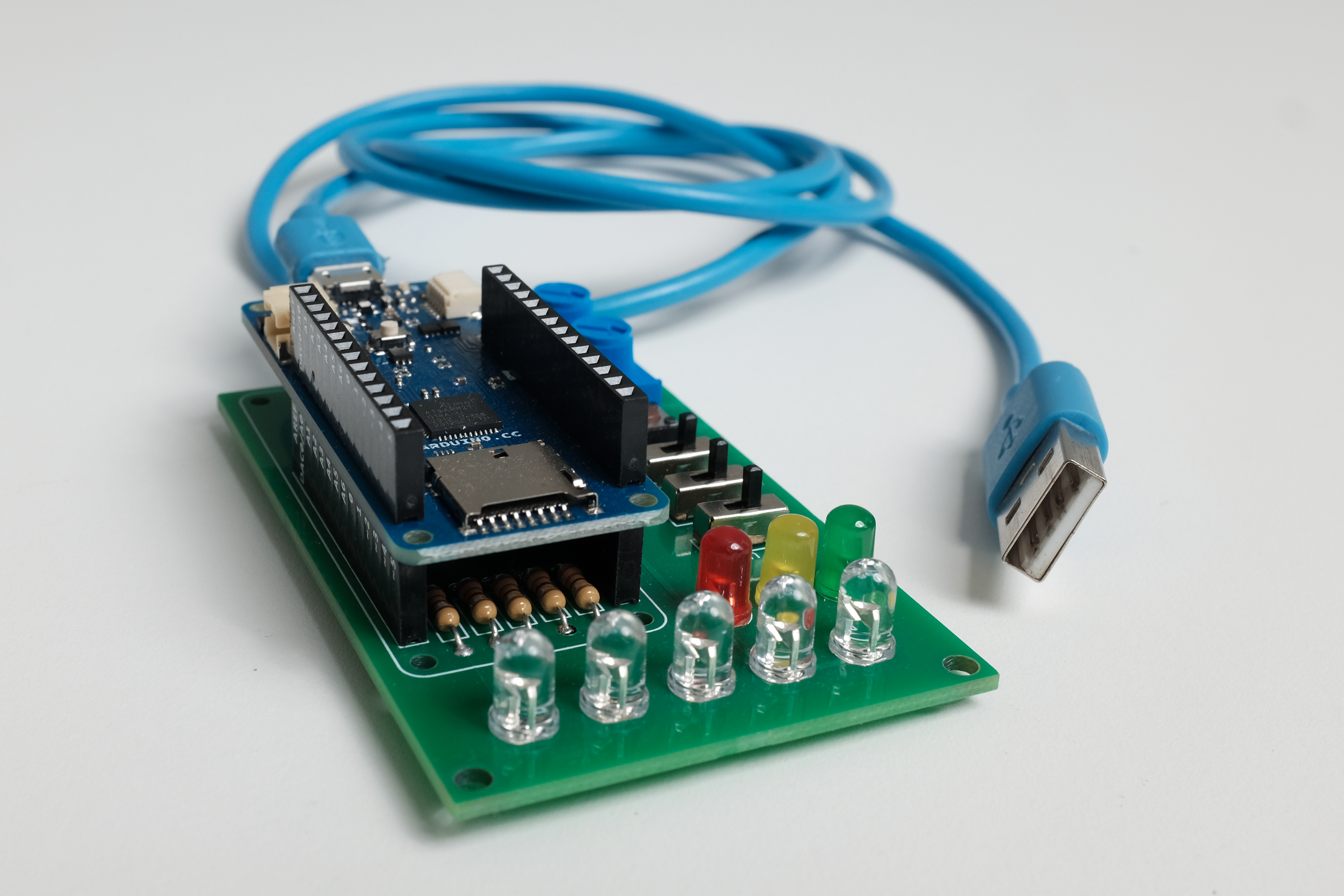

- I/O board for connecting the system to the PC (use of the LC2030 training)

Technical Data

- SIze (W x D x H): 520 x 450 x 720 mm

- Tank content: 2 x ca. 7,9 l

- Weight: ca. 26 kg

- Language of the software: German/English

Videos

Introduction to the LC2030 workstation

In this video we show the assembly of the system with all components (english subtitled).

Video is not displayed? Switch to YouTube

Closed loop control technology with the LC2030

In this video, we show you how to work on closed loop control engineering tasks with the LC2030 Training (english subtitled).

Video is not displayed? Switch to YouTube

Open loop control technology with the LC2030

In this video we show how you can use the LC2030 Training to create a sequence control with GRAFCET or a control using logic diagrams (english subtitled).

Video is not displayed? Switch to YouTube

GRAFCET using a process engineering example with the LC2030

In this video we show an example of sequence control with GRAFCET in our LC2030 training software (english subtitled).

Order details:

Order via mail

To order, please send us an e-mail with your contact details, the desired product and the number of licenses required to

Hotline / Service:

+49 (0)40 - 754 922 30

New:

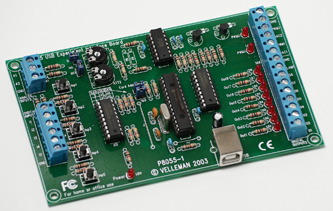

I/O Board 6288: I/O Board with USB interface

Optional accessories:

LC2030 Training (Software): Choose between the various controls or control the system via logic or GRAFCET plans [mehr].

I/O Board 6288: For the connection between LC2030 training and training system [mehr].

CC Board 1122: For manual operation of the training system [mehr].

WinErs Laborversion: Create individual control, regulation and process visualization [mehr].

More Information:

Please contact us for further information